If you have a degree in mechanical engineering or have ever worked at a workshop you would be familiar with press brake toolings. This is a machine that is designed to apply pressure to the surface of the workpiece. It's used in many industries, including food processing, metalworking, plastics manufacturing, and printing.

The tooling can be integrated into your rotary table or it can be separate from your machine. In either case, you're going to want good-quality tooling that works well at high speeds and low speeds so that you can get the most out of your investment.

What Is Press Brake Tooling?

Press brake tooling is a set of machining equipment that allows you to machine parts using the same tooling for multiple operations. This means when you start a job and finish it, your tooling can be reused for other projects. It also means that if your part has multiple steps, there will be no need for additional machines or operators.

The benefit here is cost savings: because you only need one machine instead of multiple ones and one operator instead of two or more (and therefore less overhead costs), it makes sense to invest in press brake tools rather than buying separate machines or hiring employees who operate them all day long!

Types of Press Brake Toolings

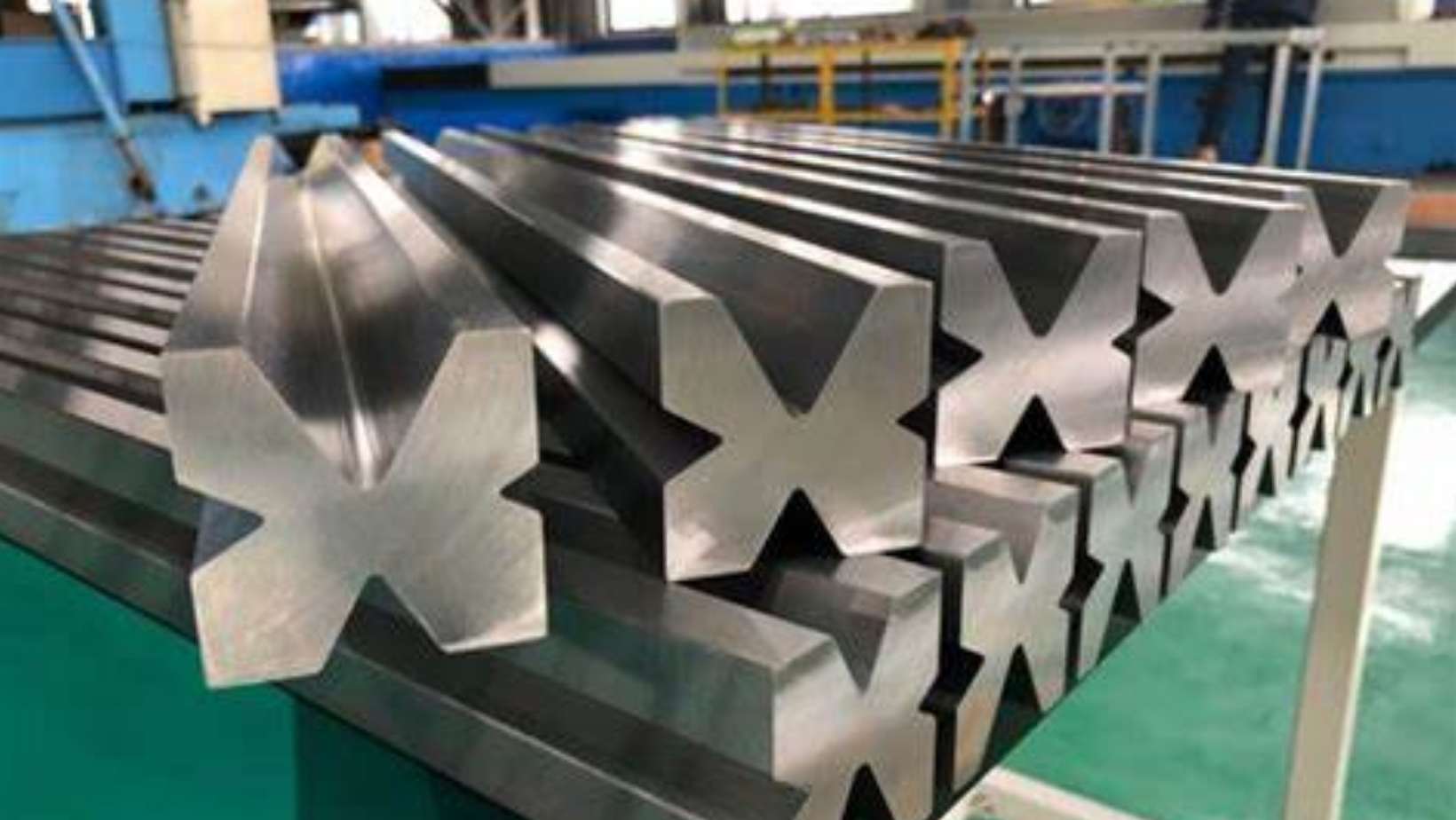

1) China Standard Style

China Standard Style is a low-priced style that can be widely used in China and other Asian countries. The material is made of high-carbon steel, but it cannot be compared to the American Precision Style or European Trumpf-Wila style because its accuracy is not as good.

China standard press toolings are available in both single and double-sided styles. Single-sided toolings have one cutting edge on each side, while double-sided toolings have two cutting edges on each side.

2) American Precision Style

American Precision tooling is used for precision parts. It's mainly used in automotive and aerospace industries, where it's made from high-grade steel and hardened to a high level of hardness.

American Precision Style is the most expensive one among these three types of press brake tooling. It's mainly used in America and Western countries but is also found in some parts of Asia as well (for example Thailand).

The main advantage of this type is that it has high wear resistance so it can last longer than other types when used on woodworking machinery like lathes & mills etc., which makes this type more suitable for long-term use at work sites where safety needs to be maintained while still being able to deliver maximum performance every time!

3) European Trumpf-Wila Style

European Trumpf-Wila Style is a high-end tooling that is designed for high precision, high accuracy and high speed. It’s also designed for high-volume production and it has a reputation for quality parts. The material used in the European Trumpf-Wila Style is chrome vanadium which has a tolerance of up to 0.0005 mm (.000001 inches) over its entire length in both directions, making it ideal for precise measurements when machining steel or aluminum alloy parts with deep crevices or complex shapes.

The adjustable nature of the European Trumpf-Wila Style makes it easier to use than standard press brake tools such as those found on most benchtop machines, allowing users with no prior experience of this type of equipment access into this niche market without having too much learning curve involved before being able to get started right away!

Conclusion

It’s important that you choose the right type of press brake tooling for your application. This will ensure that you get the best results from your machine and save money in the long run. We hope this article has helped you understand why there are three different styles of press brake tooling available on the market today and what each one does best!