TPU-coated webbing provides essential applications in both industrial settings and consumer products. This material performs well in all applications because it is strong and eco-friendly while staying useful throughout many industries. TPU-coated webbing delivers exceptional results even under harsh environmental conditions, from fashion design to medical supplies.

Sunmolin Plastic Technology Co., Ltd. functions exclusively as a manufacturer of webbing materials. The company Sunmolin started as Yunze Garment Accessories Co., Ltd in 2006 before becoming a leading TPU extrusion expert. Through over 15 years of active study and production experience with TPU materials, the company established strong technical expertise and manufacturing systems.

Differences in product requirements demand personalized solutions today. Product developers regularly encounter special needs that basic webbing cannot serve. Sunmolin, as a webbing supplier, offers custom-made solutions through precise and dependable delivery of tailored products.

Understanding TPU Coated Webbing: Composition and Advantages

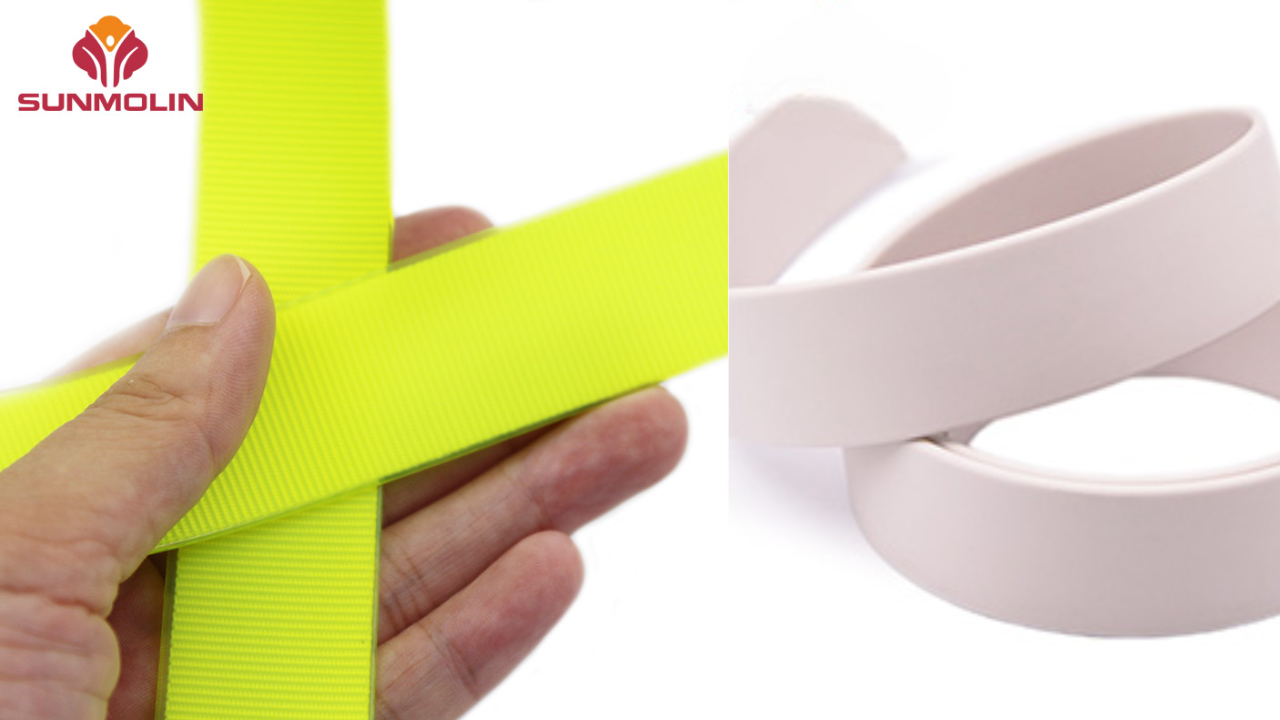

TPU combines the flexibility of rubber with the toughness as well as the durability of plastic. It remains durable in many wet and dry environments while holding up against wear and chemical damage. TPU-coated webbing holds up better than nylon and polyester webbing when handling brutal weather and temperatures.

Basic webbing materials stand in clear contrast to TPU-coated webbing features. It’s non-toxic/odor-resistant and eco-friendly. You can trust the material to remain intact without water damage or strength loss because of its robust quality. TPU-coated webbing functions well in demanding performance and safety requirements.

Sunmolin Leads the Industry with Custom Design Services

Sunmolin excels at tailoring products according to customer needs. Sunmolin adapts its services to create products that match your precise length requirements, desired shapes, and company branding needs. The precision cutting and punching maintain perfect quality, so you can start assembling right away.

Riveting creates strong and steady connections for long-lasting results. Sunmolin selects zinc-alloy rivets that offer extended resistance against rust and firm performance. Stitching serves as a lighter-weight, flexible alternative to riveting, mainly used for thin and soft webbing materials.

You can boost your brand presence through logo creation on fabric surfaces with different printing techniques. Sunmolin protects your logo placement on both webbing layers during production. The company upholds its quality standards through a decade of technical development, making sure you experience top-notch design and performance.

Diverse Surface Finishes and Aesthetic Variations

Surface finish determines whether products look good and perform well. You can pick from five surface finishes at Sunmolin, including matte, glossy, flat, colored, and embossed textures. Every surface texture brings unique sensations plus specific uses. The matte finish fits gear designed for rough outdoor activities, whereas the glossy surface looks elegant for luxury product lines.

Need a specific color? Sunmolin can reproduce Pantone shade standards to match your brand specifications. When your product stands apart, you can customize unique shape designs and raised surface textures. These different webbing choices let you create styles that match your product’s specific design and purpose.

Functional Adaptability Across Industries

TPU-coated webbing meets design requirements for many different industrial applications. Medical tools use TPU webbing because it helps protect patients and stays flexible during use.

TPU webbing supports fire-resistant handles in public transportation systems. TPU coating transforms fashion products by creating new looks for bags and cosmetic items. The material demonstrates its ability to meet style needs plus deliver safety performance in demanding conditions.

Innovative Production Technologies and Quality Control

Sunmolin produces high-quality products through methods like double and multideck extrusion. These production methods help build TPU layers that boost performance and design flexibility. The company runs six memorable production lines to create TPU-coated webbing products faster and expand its output capacity.

Precision matters in every batch. The production team works stringently to maintain reliable measurements. Sunmolin guarantees precise dimensions and consistent product quality for small sample orders and big production runs.

Sustainable and Safe Material Choices

TPU offers both durability and environmental responsibility. Sunmolin selects eco-friendly TPU materials that produce no odor and pose no health risks. The materials fulfill strict health and safety criteria needed to make medical equipment and children's products.

Sustainability matters more than ever. TPU helps protect the environment better than PVC or regular synthetic materials because it offers reduced lifetime environmental effects. Sunmolin continues to make production choices that reduce its environmental impact while getting raw materials from sustainable sources.

Conclusion

Sunmolin Plastic Technology Co., Ltd. maintains its position as a leader in specialized TPU-coated webbing production. Through its advanced manufacturing lines and research facilities, the company provides customized solutions to different market sectors.

TPU-coated webbing adds superior performance benefits across the fashion and transport sectors, as well as healthcare. Sunmolin's advanced webbing technology, plus its material and business responsibility, make this company a dependable partner worldwide. As market demand increases for eco-friendly materials that excel at high-performance, Sunmolin stands ready to support product development.