Petrochemicals, oil and gas, and chemical processing industrial sectors are the sectors where the choice of pumps is crucial to efficiency, safety, and cost management in the long term. Out of the vast array of options, the mechanical seal pump and the old-fashioned pump are the most common debate. Although both are aimed at the same mission of fluid flow, the technologies, the way they are performed, and their applicability in particular environments are quite different. The engineer, procurement teams and the operators of plants are required to understand these variations in order to assure efficient operations in such high-stakes industries.

Defining Traditional Pumps

The conventional pumps either employ packing or less complicated sealing mechanisms to regulate fluid leakage. Packing is the act of compressing a soft material on the pump shaft to limit the amount of fluid flowing through it. The disadvantage of this method, despite the fact that it has been in use for decades and is easy to maintain, is that it has limitations in its nature. High pressure or temperature can wear out the packing system quite quickly, resulting in regular adjustments, more leakage, and safety hazards. These pumps can be satisfactory in less demanding services, but in such services, where toxic, corrosive or high-temperature fluids have to be processed, modern industry requirements frequently exceed their traditional design.

The Evolution of Mechanical Seal Pumps

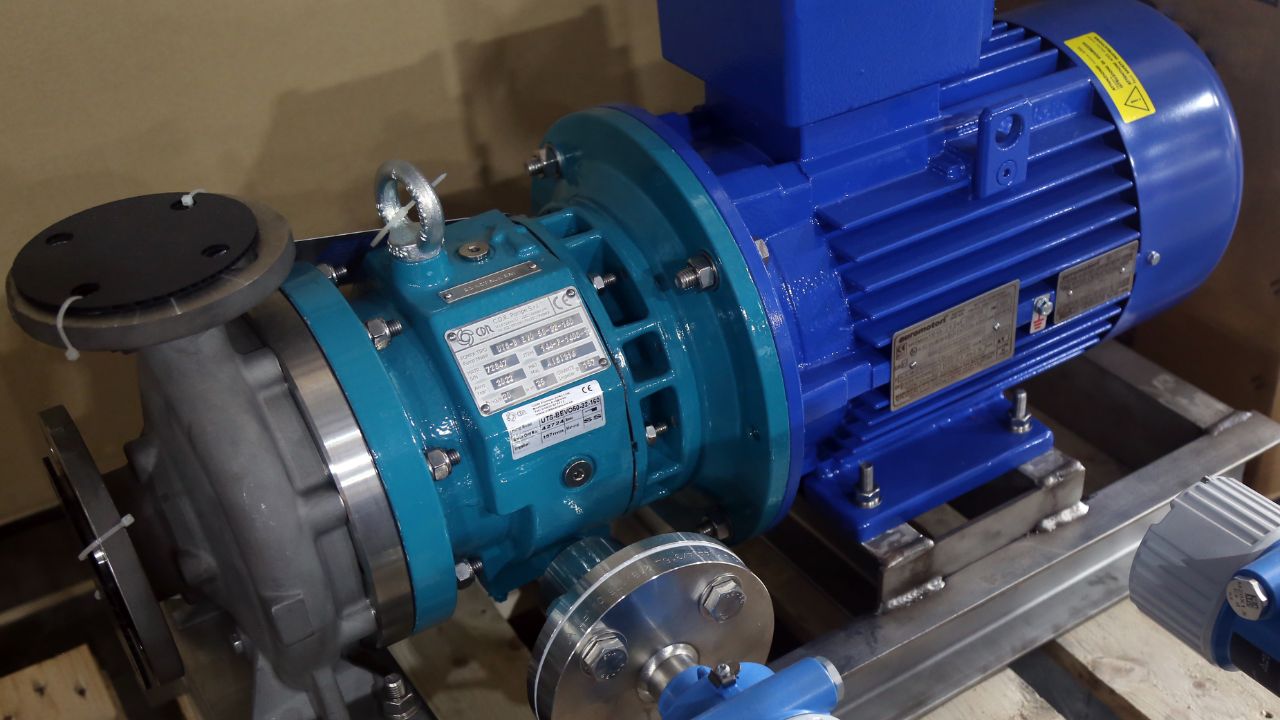

Mechanical seal pumps were invented to counteract the flaws of the old sealing processes. They do not use packing material, but instead rely on precision-engineered seal faces usually composed of a material (such as carbon or silicon carbide) that presses against one another tightly to seal without leakage. These seals have the ability to withstand high rotational rates, high temperatures, corrosive and hazardous fluids, much more effectively than outdated systems. Minimizing leakage and improving maintenance periods have made mechanical seal pumps the norm in any industry that requires reliability and safety in extreme conditions.

Leakage Control and Safety

Leakage control is one of the most important distinctions that can be made between the two technologies. Conventional pumps with packing seals will leak some amount of fluid, bypassing the seal system, which could be tolerable in other situations with water or benign chemicals, but is problematic when there is a hazardous material to be transferred. In comparison, mechanical seal pumps are created to attain close to zero leakage. This means they are suitable in petrochemical plants and refineries where any small leakage may cause an environmental risk, a safety risk, and a regulatory punishment.

The advantages to safety are obvious: it lowers the risk of harmful fluid leakage so that, in keeping both human and equipment out of the way of the hazardous substances or the excessive-temperature media, the mechanical seal pumps would ensure safer working conditions.

Maintenance and Lifecycle Costs

The other significant difference is the maintenance needs of either type of pump. Conventional pumps can require frequent repairs with frequent changing of packing material as well, which increases downtime and labor costs. In the long run, such repeated interventions contribute a lot to operating expenses.

Mechanical seal pumps, though more complex initially, offer longer service intervals and reduced maintenance demands. Even after years of use, the well-designed seals can last, thus reducing the labor spent on them and leading to minimal expenses on interruptions in the production process. The initial cost of a mechanical seal pump can be more, but overall ownership is often significantly less with less maintenance and longer life.

Performance under Harsh Conditions

Mechanical seal pumps are evidently superior to the traditional designs when working in conditions of high pressures, high temperatures or corrosive chemical substances. Their designed seal systems are able to resist punishing conditions without much wear as compared to packing systems in conventional pumps, whose performance deteriorates quickly when subjected to the same conditions. This renders mechanical seal pumps as the choice in terms of the oil and gas industries, whose process stability and equipment life are critical.

It is possible that the traditional pumps could still be needed in some basic applications like water transfer in less demanding facilities; however, it has been seen in critical areas that mechanical seal technology is a necessity.

Conclusion

The variations between mechanical seal pumps and conventional pumps lie in the design, safety, maintenance, and performance. Although traditional pumps are economical in low-hazard environments, they fail to support the demands of contemporary industrial operations that presuppose hazardous or extreme working conditions. Mechanical seal pumps, on the other hand, are superior in leakage control, safety measures, low maintenance and their overall performance. The decision is obvious when it comes to the industries in which reliability and safety cannot be neglected. The pumps that are known as mechanical seal ones are one of the key innovations in pump technology that can guarantee effective operations and a sense of security even in the most demanding working conditions.