Advantages of heat sink

The use of a heat sink offers several advantages in electronic devices. Here are some of the primary advantages of using a heat sink:

- Temperature Control: One of the primary advantages of using a heat sink is that it helps to control the temperature of electronic devices. Heat sinks absorb and dissipate heat away from the device, which prevents overheating and prolongs the lifespan of the device. Nonetheless, to get the best results, you have to obtain a heat sink supplier who is well reputated in their services.

- Improved Performance: Heat sinks can improve the performance of electronic devices by preventing thermal throttling. Thermal throttling occurs when the device reduces its performance to prevent overheating, which can cause a reduction in speed and performance.

- Reliability: By preventing overheating, heat sinks increase the reliability and durability of electronic devices. Overheating can cause damage to components and lead to premature failure of the device.

- Compact Design: Heat sinks allow for more compact and lightweight designs of electronic devices by eliminating the need for additional cooling components, such as fans.

- Cost-Effective: Heat sinks are cost-effective compared to other cooling solutions, such as liquid cooling systems, which can be expensive and complex.

- Silent Operation: Passive heat sinks do not require any fans or other mechanical components, resulting in silent operation.

Nonetheless, heat sinks are essential in ensuring the reliable and efficient operation of electronic devices by controlling their temperature and preventing overheating.

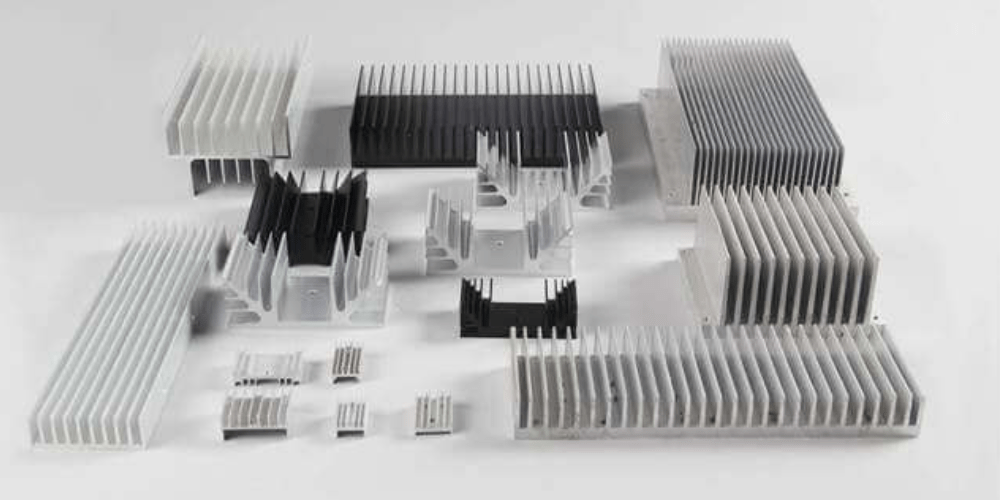

Developing heat sink through CNC machined process:

Firstly, it is possible to develop heat sinks through CNC (Computer Numerical Control) machining. As, CNC machining is a manufacturing process that uses computer-controlled machines to remove material from a workpiece to create a custom-designed part or product. Therefore, heat sinks can be machined from various materials such as aluminum, copper, and brass, which are known for their high thermal conductivity.

CNC machining allows for precise and accurate manufacturing of heat sinks with complex shapes and features that are designed to optimize thermal performance. The use of CNC machining also enables the production of heat sinks in small and large quantities with consistent quality.

The process of developing a heat sink through CNC machining involves designing the heat sink using computer-aided design (CAD) software, which is then used to generate a digital model of the heat sink. This digital model is then uploaded into the CNC machine, which uses cutting tools to remove material from the workpiece to create the heat sink.

Which material works best for CNC machine process of heat sink:

There are several materials used to make heat sinks through CNC machining, and the choice of material will depend on the specific thermal requirements of the application. Here are some of the most commonly used materials for CNC machined heat sinks:

Aluminum: Aluminum is a popular choice for heat sinks as it has high thermal conductivity, is lightweight, and has good corrosion resistance.

Copper: Copper has high thermal conductivity, making it an excellent choice for high-performance heat sinks.

Brass: Brass is an alloy of copper and zinc and is often used as a heat sink material due to its high thermal conductivity and excellent corrosion resistance.

Lastly, CNC machining can produce high-quality heat sinks with tight tolerances and precise dimensions, making it a popular manufacturing method for heat sinks used in electronic devices.